Metal Foundry: Reducing Operational Costs

A Look at the Future: Fads Shaping the Future Generation of Aluminum Foundries

The aluminum shop market stands on the brink of substantial change. Automation and progressed modern technology guarantee to reshape manufacturing procedures. Sustainability methods are coming to be necessary to fulfill ecological standards. As customization needs increase, the requirement for versatility in manufacturing grows. Collaborative initiatives with technology companions might drive advancement. These emerging fads recommend an essential change awaits. What difficulties and possibilities lie ahead for aluminum factories in this progressing landscape?

The Rise of Automation in Light Weight Aluminum Foundries

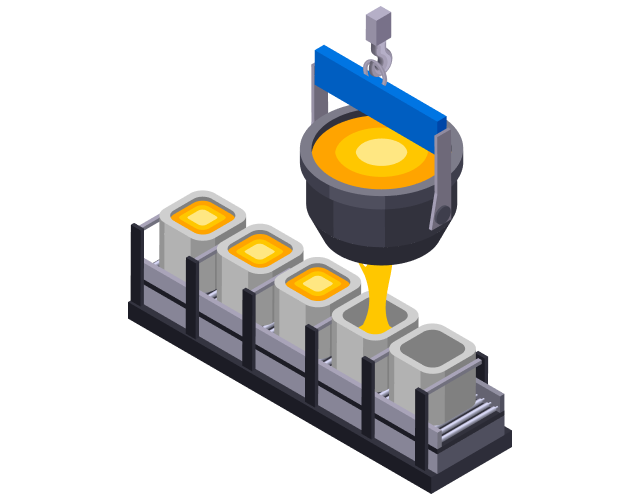

The integration of automation in light weight aluminum foundries is improving the industry landscape. As suppliers adopt advanced innovations, processes typically reliant on manual work are ending up being increasingly automated. This shift not just boosts manufacturing effectiveness yet likewise reduces human error, resulting in a much more consistent item top quality. Robotics and man-made intelligence systems are being used for jobs such as mold preparation, putting, and finishing, streamlining operations and lowering preparations.

Additionally, automation promotes the collection and analysis of data, making it possible for factories to enhance their procedures continuously. Anticipating upkeep powered by sensors helps in anticipating tools failings, causing lowered downtime. The workforce is also developing, as employees are adjusting right into functions that need oversight of automated systems, concentrating on higher-level analytical and development. On the whole, the increase of automation in aluminum shops stands for a substantial evolution, placing the industry for enhanced productivity and competition in a rapidly transforming market.

Welcoming Sustainability Practices

Light weight aluminum shops are increasingly taking on sustainability practices to deal with ecological problems. Trick initiatives concentrate on recycling and reuse of materials, alongside technologies targeted at enhancing power performance. Aluminum Foundry. These initiatives not just lower waste however also add to an extra lasting production process

Reusing and Reuse Initiatives

A considerable shift towards sustainability is improving the landscape of aluminum foundries, with many adopting cutting-edge recycling and reuse campaigns. This movement highlights the value of reducing waste and optimizing source performance. Shops are significantly implementing closed-loop systems, permitting scrap light weight aluminum created throughout manufacturing to be recycled and reintegrated into the manufacturing cycle. Furthermore, collaborations with local recycling facilities promote the collection of post-consumer light weight aluminum, better sustaining sustainable techniques. By utilizing advanced sorting innovations and reusing approaches, these factories improve the top quality of recycled materials, guaranteeing they fulfill industry requirements. In general, these initiatives not only decrease ecological effect however likewise contribute to cost financial savings, placing aluminum foundries as leaders in lasting manufacturing within the steel industry.

Energy Effectiveness Innovations

Countless aluminum foundries are welcoming energy efficiency technologies as component of their sustainability practices. These innovations consist of the combination of sophisticated modern technologies such as automation, expert system, and power monitoring systems. By enhancing manufacturing processes, factories can significantly lower power usage while preserving output high quality. In addition, many are buying renewable resource resources, such as solar and wind, to power their procedures, better decreasing their carbon footprint. Using energy-efficient heaters and recycling warmth generated during manufacturing is also becoming commonplace. These techniques not only add to ecological sustainability yet additionally result in cost financial savings for foundries. As the market develops, the dedication to energy efficiency will likely play an important duty fit the future of aluminum production.

The Impact of Expert System

As the light weight aluminum factory market progresses, the assimilation of synthetic intelligence (AI) is becoming significantly significant. AI innovations are changing production procedures by boosting operational effectiveness and minimizing waste. Anticipating analytics, powered by AI, enables shops to visualize prospective devices failures, making it possible for aggressive upkeep and reducing downtime. Additionally, AI-driven algorithms improve casting designs, resulting in enhanced material usage and enhanced product quality.

AI promotes real-time surveillance of production specifications, enabling prompt adjustments to preserve optimal conditions. This adaptability not just improves product consistency but also supports energy-efficient practices. By evaluating huge quantities of data, AI can determine patterns and understandings that human drivers could forget, driving constant improvement. As these innovations end up being a lot more available, the light weight aluminum factory sector is positioned to take advantage of AI to attain higher accuracy and technology, inevitably forming an extra sustainable and competitive future in manufacturing.

Additive Production Innovations

Additive production is quickly transforming aluminum foundries by boosting layout abilities and enabling a lot more intricate geometries. This development not only permits greater imagination in item development yet also helps with economical manufacturing approaches. As these technologies progress, they guarantee to redefine standard production procedures in the market.

Improved Design Capacities

Development in design capacities has transformed the landscape of aluminum shops, specifically through the integration of additive manufacturing innovations. This development allows for greater flexibility in developing intricate geometries that were formerly unattainable with traditional methods. Shops can now develop light-weight frameworks optimized for performance and capability, lowering material waste and boosting energy efficiency. Furthermore, the quick prototyping capacities of additive production allow quicker versions and improvements, cultivating innovation in product development. Collaboration between style designers and factory professionals has additionally been enhanced, bring about a lot more reliable interaction and enhanced end products. As these technologies proceed to advance, the capacity for tailored options tailored to details applications will better redefine the future of light weight aluminum shops.

Cost-Effective Manufacturing Approaches

Arising fads in cost-effective manufacturing methods have actually revolutionized the light weight aluminum shop industry, especially via advancements in additive manufacturing. This modern technology allows the fast production of complicated geometries with lowered product waste, substantially lowering prices. By making use of 3D printing strategies, factories can produce elaborate components that typical approaches struggle to accomplish, enhancing design flexibility. In enhancement, additive production enhances prototyping processes, permitting quicker iterations and faster time-to-market. These developments not just maximize production efficiency but likewise contribute to sustainability initiatives by decreasing scrap. As light weight aluminum shops progressively take on these techniques, they position themselves to fulfill expanding need while preserving affordable prices, inevitably changing the landscape of aluminum manufacturing.

Enhancing Quality Assurance Measures

Many foundries are implementing standardized operating procedures and rigorous screening methods. By cultivating a society of liability and constant renovation, they aim to reduce variants in manufacturing high quality. Educating programs for employees are also being prioritized to protect that personnel are well-versed in quality control techniques. Inevitably, these improved quality assurance determines not just improve product dependability yet also boost the credibility of light weight aluminum shops in an affordable market, leading the way for long-lasting success and sustainability.

The Change In The Direction Of Modification and Versatility

As aluminum foundries boost their quality assurance steps, they are also replying to a boosting need for customization and flexibility in manufacturing - Metal Casting. This shift is driven by developing client choices and the need for specialized items throughout different markets. Foundries are adapting their processes to fit lower quantity runs and customized styles, allowing them to satisfy click this site details client needs a lot more effectively. Advanced technologies, such as additive production and computer-aided layout, are promoting this change by permitting fast prototyping and adjustments, thereby lowering preparations. Additionally, the combination of smart production methods boosts the adaptability of assembly line, allowing shops to pivot quickly in action to market adjustments. The focus on customization not only improves client satisfaction yet likewise settings shops to continue to be competitive in a dynamic market landscape, paving the way for innovation and diverse product offerings in the light weight aluminum market

Partnerships and Collaborations in the Market

Collaborations with research institutions facilitate the advancement of new alloys and sustainable practices, addressing environmental worries and governing needs. These collaborations likewise aid in knowledge sharing, allowing companies to adopt ideal methods and rapidly implement technological improvements.

Tactical partnerships with distributors ensure a secure supply chain for raw products and advertise cost efficiencies. As the industry faces challenges such as labor shortages and boosting competitors, these partnerships are critical in driving development and development. By interacting, light weight aluminum foundries can much better browse the complexities of the marketplace and attain long-term success.

Regularly Asked Concerns

What Are the First Costs of Automating an Aluminum Foundry?

The preliminary costs of automating an aluminum factory can range considerably, usually between hundreds of thousands to numerous million dollars, relying on the degree of automation, equipment top quality, and specific functional requirements of the center.

Just How Can Small Foundries Take On Sustainable Practices Effectively?

Little foundries can take on sustainable methods properly by carrying out energy-efficient technologies, recycling scrap products, optimizing procedures to reduce waste, and making use of environmentally friendly products, promoting a society of sustainability amongst staff members via training and understanding initiatives. Aluminum Foundry.

What Duty Does Information Safety And Security Play in AI Applications?

Information safety and security is necessary in AI applications, guaranteeing the defense of sensitive details, keeping customer depend on, and protecting against unapproved gain access to. By executing durable safety actions, organizations can protect data stability and promote compliance with guidelines.

How Will Ingredient Manufacturing Affect Conventional Casting Strategies?

Additive manufacturing will improve conventional spreading techniques by enabling a lot more complicated geometries, minimizing material waste, and reducing manufacturing times. This combination might bring about a hybrid technique, optimizing efficiency and increasing style opportunities in production.

What Abilities Will Be Many popular in Future Light Weight Aluminum Foundries?

In future light weight aluminum foundries, skills in additive manufacturing, information analysis, automation, and sustainability practices Find Out More will certainly be paramount. Workers proficient in advanced technologies and environmentally-friendly processes will be in high demand, driving market innovation and effectiveness.

Factories are progressively executing closed-loop systems, permitting scrap aluminum produced throughout manufacturing to be reprocessed and rehabilitated into the important source manufacturing cycle. Additive production is quickly changing aluminum factories by boosting design capabilities and allowing extra intricate geometries. Technology in layout capabilities has actually transformed the landscape of light weight aluminum shops, specifically via the assimilation of additive manufacturing innovations. Arising trends in cost-efficient manufacturing methods have actually changed the light weight aluminum foundry market, especially via developments in additive production. As light weight aluminum factories enhance their quality control measures, they are likewise responding to an increasing demand for personalization and adaptability in manufacturing.